Whether your customers want them, or you just like them better for one reason or another, I think you should make sure you are looking at the total cost involved before you commit to a purchase of canning equipment.

Canning equipment runs the gamut from filling one can at a time by hand to piling up thousands of cans an hour. With this variation come a lot of differences in how complicated the equipment is and how difficult it can be to set up and operate.

Some equipment will require professional installation and training of your folks on how to operate it. Make sure the prices you are looking at are complete, installed, trained up and ready to run. Another consideration here is turnover. If you have employees trained up to operate your canning line and they leave your employ, you will have to start that training process all over again, sometimes requiring you to pay a company rep to come out or take a lot of your time to train them.

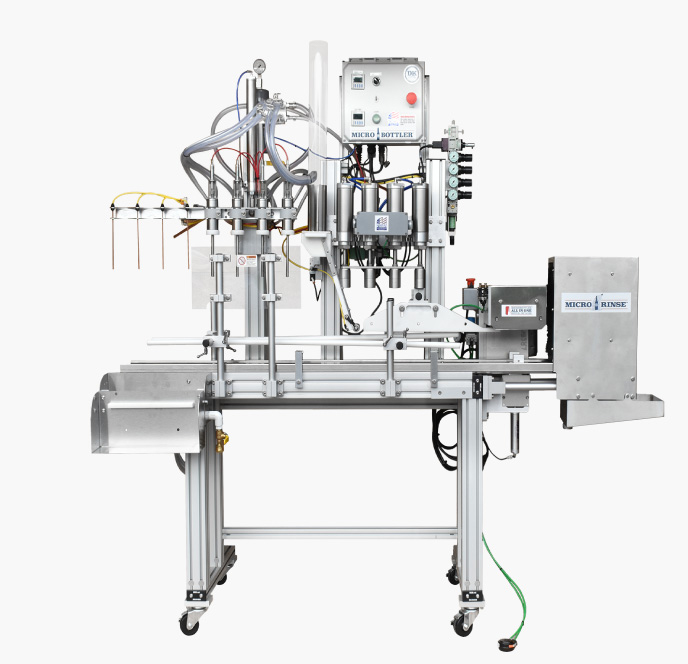

The MicroFilling line of products are simple to setup and use. After watching a short video and running thru a simple training program that is printed in the owner’s manual, you are ready to fill bottle or cans (did I mention that we are the only packaging solution that does both?).

When looking at options remember that the time you spend setting up, tearing down, cleaning and adjusting your machinery is all time – and time is money. With our filling line the setup is simple, just plug it in, connect the air and CO2 lines and you are ready to fill. When you’re done, you rinse it off, blow it dry and you can tuck it away until next time.

Another consideration is floor space. Real estate taxes, HVAC, maintenance, insurance – you pay for every inch of floor space in your operation so look closely at the space commitment you will have to make to accommodate your canning line.

The MicroBottler with the modular canning attachment takes up less space than some pets. At less than 6’ long, and 2’ deep it will fit almost anywhere. With its wheeled base, you can roll it right up to your tanks on bottling day and when you are finished, cover it up and roll it right thru a standard doorway and store it anywhere. You can store it in a closet if you need to.

Some filling lines require complicated maintenance programs that take you or your employees away from the task at hand. With the MicroBottler there is almost no maintenance. Keep it clean and hit a few lubrication points with a grease gun and it’s good to go for next time. It’s a very durable and simple machine that wont have you doing complicated disassembly/cleaning/lubricating/reassembly procedures to keep it ready for use.

Parts availability is a common malady for some packaging lines but not with us. Unavailable parts cost you money in the form of down time and we understand this. Our machine was designed to use simple off the shelf parts when possible. We are not in the “Parts business” like some of our competitors, who base their business model on selling you parts down the road.

The owners manual of the MicroBottler contains parts breakdowns as well as part numbers and contact information for many commodity items (fittings etc.) so you can buy them directly from the same source we get them from. Several items may be available at your local hardware store. All of the other custom made parts are made in our shop and always in stock for quick shipment if you ever need parts support for your machine.

Technical support is a sore subject with some people we have talked to after they purchased the wrong packaging solution. Some companies simply don’t support their product- which can cost you dearly. Some companies want to charge you to send someone out to work through your issues.

With the MicroFilling system, our tech support is always free and always ready to help you with anything that may arise. Whether you are having problems connecting your machine, difficulties dialing in your product fill or have questions about repairs or maintenance.

Even if you bought your machine years ago and you need us to talk a new employee through some sort of problems, we are always here to help – free forever.